Brief description of the boiler

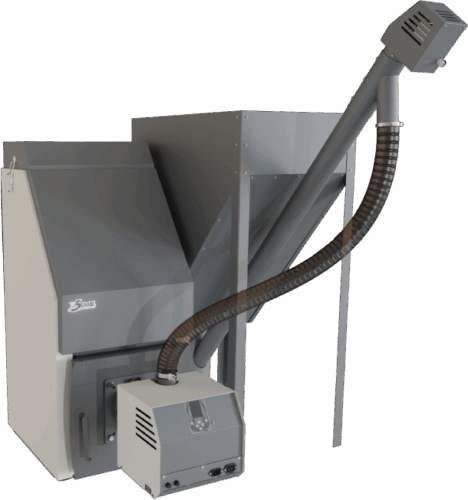

The GREYKO EXTREME pellet boiler is a steel hot water boiler with a water jacket. It is class 5 according to the BDS EN 303-5:2021 standard and is intended for connection to heating installations of single-family houses, administrative buildings and workshops .

The boiler has a highly efficient three-pass heat exchanger with vertical flue pipes and operates in a non-condensing mode. The internal casing of the combustion chamber is made of high-quality sheet steel with a thickness of 5 mm . Efficiency up to 92.2% is achieved at reduced power and can operate with wood pellets, agropellets and combined pellets .

Greyko RB 20 is the only pellet burner that has successfully proven itself in burning pellets of any quality without straw pellets, without having to stop the combustion process for self-cleaning, and without cleaning the hearth. The innovative and unique combustion head on our market does not allow the retention of slag and other silicates that interfere with combustion.

Technical characteristics

| Model | Dimensions | Extreme 20 |

|---|---|---|

| Rated power | kW | 19.8 |

| Reduced power | kW | 6.63 |

| Maximum working pressure | Bar | 2 |

| Test pressure | Bar | 4 |

| Maximum water temperature | ℃ | 90 |

| Flue gas temperature at nominal power* | ℃ | 99 |

| Flue gas temperature at reduced power* | ℃ | 51 |

| CO emissions (10% oxygen) at rated power | Mg/m3 | 449 |

| CO emissions (10% oxygen) at reduced power | Mg/m3 | 353 |

| Type and size of fuel material | Wood pellets, agropellets, combined pellets | |

| Overall dimensions H/W/D | mm | 1625/529/1378 |

| Pellet consumption | kg/h | 4.625 |

| Water jacket volume | 98 | |

| Type of expansion vessel for the installation | Closed | |

| Hopper capacity: boiler mounted / freestanding | kg | 115/150 |

| NET weight | kg | 262 |

| Chimney draft | Yes | 12±2 |

| Inlet pipe D2 | 1 1/4" | |

| Outlet pipe D1 | 1 1/4" | |

| Thermowell D3 | mm | M12x1.5 |

| Flue diameter - M | mm | 148 |

| Distance of the thermowell between inlet and outlet pipes A/B | mm | 240/781 |

| Distance between inlet and outlet pipes E/F | mm | 771/240 |

| Efficiency at rated power* | % | 91.23 |

| Efficiency at reduced power* | % | 92.2 |

* Results when working with a GREYKO RB / RB STAR burner and C1 class pellets.

Advantages of the burner

- Working with any type and quality of pellets - wood and agropellets (excluding straw).

- Quick installation and setup – 4 hours by 1 person.

- It is not necessary to clean the burner.

- Modulation – three levels of power regulation.

- Self-cleaning without interrupting the combustion process.

- Reliable electric heater – 10,000 life cycles.

- Low power (consumption) of electric heater – 121 W. Quick ignition ≈ 2 min.

- Non-combustible flexible pipe – flamex.

- Inability to achieve “reverse flame”, even with the flexible tube removed.

- Inlet pipe overflow protection.

- Cold burner body and tube during operation.

- The photoprobe cannot be dusted, smoked or melted.

- "Keep the fire going" function.

- Vertical flame.

- Possibility of control from a room and programmable thermostat.

- Easy installation.

- Easy start-up and setup.

- High combustion efficiency – preheating and gas separation.

- Possibility of direct installation of oil boilers without conversion (set of 2 flanges).

- Easy operation.

- Easy cleaning.

- Possibility to include a DHW pump.

- Competitive price of the received heat energy.

- Does not pollute the environment.

- Compatible with all solid fuel boilers without the need for reconstruction of the heating installation.

- Fully automated.